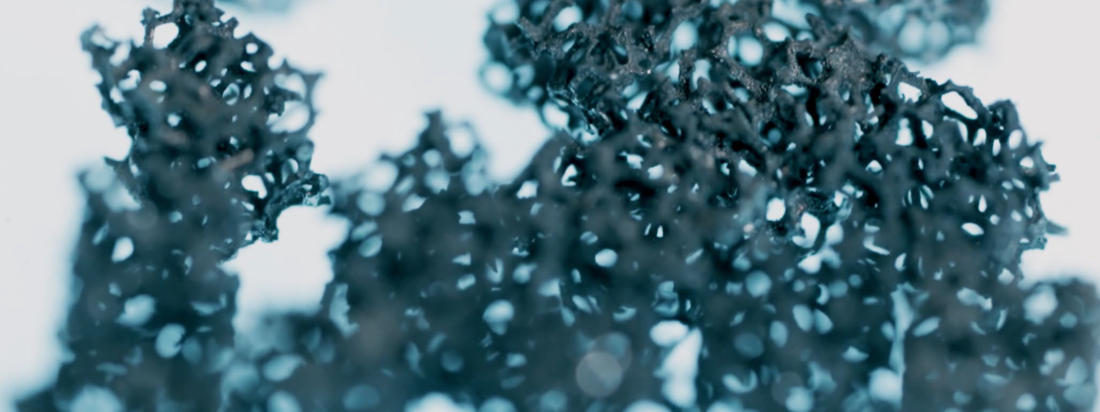

Innovative technologies

Most chemical processes use catalysts in granule, extrudate, tablet or powder form. At Evonik, we are constantly asking ourselves how to make a difference. That’s why we have developed a much better alternative to conventional catalysts for fixed-bed applications. Our innovative metal foams are a game changer. They perform better, are more efficient and sustainable. ... MORE